At RoadRunner Recycling, we scream for clean-stream! When it comes to separating materials, retaining their value, and responsibly disposing of them, clean-stream is far and away the best method for doing so. There's a whole lot of good to shout about here - read on to learn more about the recycling debate and why we're team clean-stream all the way!

Consumer Confusion: Which Bin is Which?

If you feel you need an advanced degree to recycle successfully, you're not alone. With countless rules, bins, materials, numbers, symbols, and signs - there's a whole lot to keep straight. In fact, people everywhere report confusion about when, where, and what they should recycle. An ISRI and Earth911 study reported that 65% of respondents don't understand which plastics are recyclable. The confusion transcends material type, and unfortunately, too much of this confusion translates into more trash. A Call2Recycle study reported that when people are on the fence about whether to recycle an item, 50% throw the item away as trash.

Here's where some of that stems from: recycling materials responsibly is a more involved process than it seems. Countless factors impact this process, including: different government mandates and regulations, material types (and the contaminating residue often left in them), along with regional facility locations and capabilities. Throw in the mix some real quandaries - materials that are philosophically possible to recycle, but economically irresponsible to reclaim (we're looking at you, Styrofoam). This results in a profusion of recycling myths and methods, which has generated a very lively debate - and much more confusion - about how best to recycle. Let's explore this some more...

WHY ARE THERE SO MANY KINDS OF RECYCLING?

The short of it: there's no universal recycling code. Without this consistent standard, there is no system in place to guide the process, creating discrepancies nationwide. The problem has become so acute that what may be considered recyclable in one township, may be collected with the trash the next county over. Indeed, an engineering student created the ubiquitous recycling symbol in 1970, his casual (and winning) entry to a design competition. While now globally recognized, the symbol is not associated with any standards. No regulating authority monitors the symbol's usage, which makes it an unreliable indicator of an item's recyclability. Always the best move: check-in locally to see what is accepted.

Even once you've memorized your local recycling rule book, the materials themselves are often designed to be misleading. Unfortunately, as consumer interest in "green" brands has been skyrocketing, companies are responding with product labels that frequently make feel-good, but meaningless and unsubstantiated proclamations. Manufacturers adorn their products with a whole slew of unregulated terms, eye-catching phrases like "bio-based," "plant plastic," "eco-friendly," "natural," and "sustainable." In a recent audit, consulting firm TerraChoice discovered that 95% of so-called "eco-friendly" products were notably less green than labeled. Often, these labels are over-hyped; at worst, they fabricate standards.

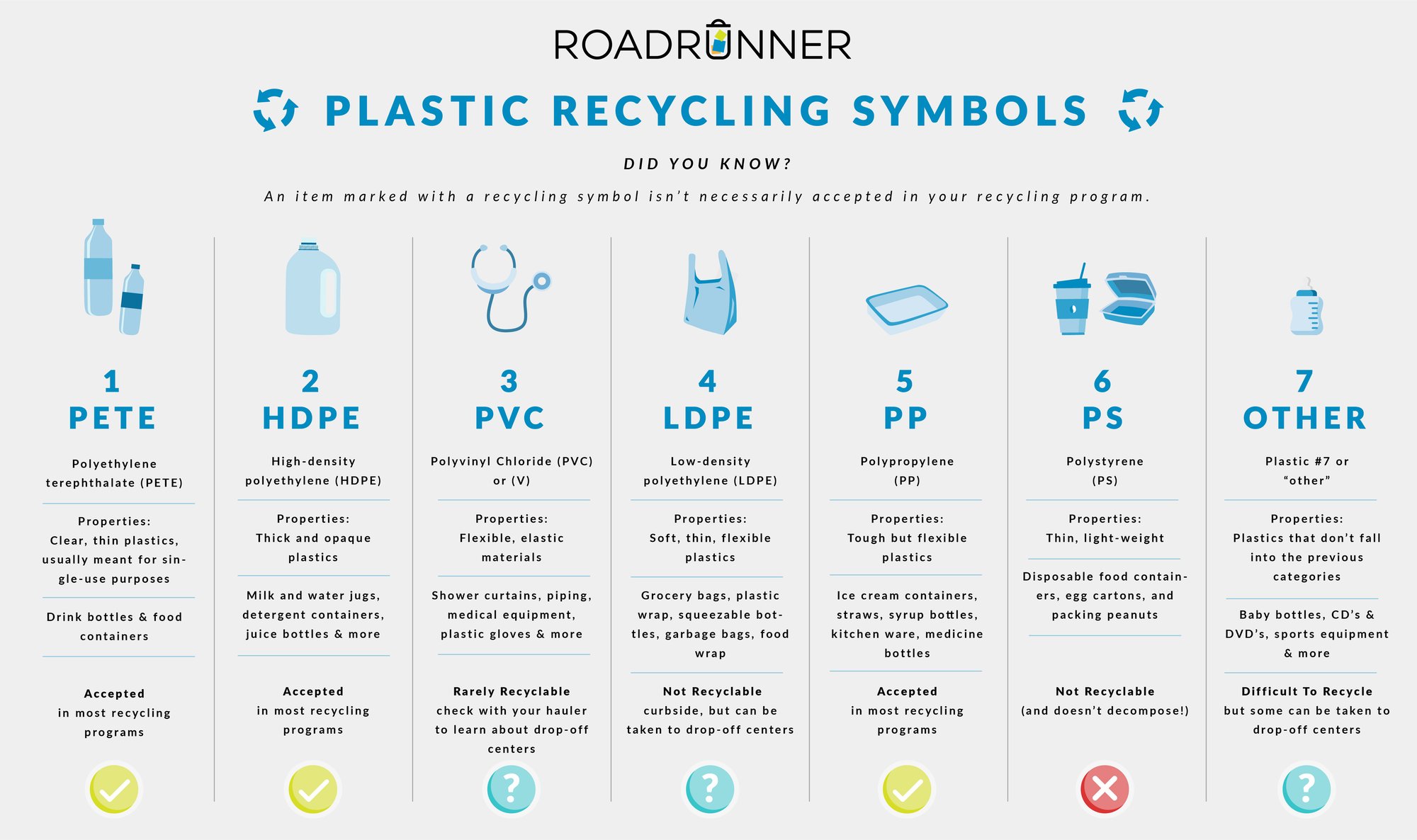

The Resin Identification Codes signal the type of plastic used in the product; but, contrary to widespread consumer belief, do not necessarily indicate whether the item can or cannot be recycled.

Spoiled by Single-Stream

One bin for all recyclables - seems simple enough. When single-stream took off in California in the 1990s, many thought it would solve the industry's woes. The logic went: remove the burden of sorting from the consumers, and increase the recycling rate. That part was true, material intake skyrocketed, and by 2010, more than 2/3 of US districts with recycling programs had adopted it. See our post on the history and hazards of single-stream here.

However, what the industry failed to account for was the quality of all this new material they were bringing in. Higher volumes, yes, but in the form of lower quality hauls. No matter the collection method - whether it's consumers at source or workers at facilities - sorting must occur. And the problem with end-separation is contamination: when you stick a molding yogurt container in with a shampoo bottle, in with magazines and newspapers, beer bottles and takeout containers, glass shards, and food particles are going to wind up coating everything. On the subject of single-stream, Susan Collins, Director of the Container Recycling Institute, often says: "You can't unscramble an egg." Thrown into the same bin, the materials are all mixed up and exposed to contamination - at best downgrading them, but at worst, rendering them "residuals" unfit for reclamation. Collins noted that about 25% of single-stream recycling is ultimately rerouted to landfill.

Single-stream contamination is not an inexpensive problem, either. Waste Management, one of the largest single-stream recyclers, reported a $16 million recycling loss in Q1 2015. "Single stream recycling results in a doubling of contamination rates," says Susan Robinson, Waste Management's Director of Public Affairs. Cities are feeling it as well. A recent Washington Post article cites that recycling material processing rates jumped to nearly $63/ton after implementing single-stream collection. That rate is 24% higher than the costs of sending these recyclables to the incinerator, along with the regular trash. Lower market demand has also decreased reclaimed material values. At this year's Waste Expo Conference, Michael Timpane, Affiliate VP for RRS said that single-stream commodities are hovering near a 6-year low, and have dropped from about $125 to about $71/ton.

WHY WE'RE TEAM CLEAN-STREAM

While it's hard to dispute the logic of using just one blue bin to capture all recyclables, RoadRunner Recycling practices the clean-stream philosophy because of the emphasis it places on retaining a material's end value. The cleaner a material, the more likely it is to be successfully recycled - and we're all about cleaning up the recycling process.

We believe the pros of clean-stream recycling more than make up for the slight reduction in consumer convenience. Whether you call it 'clean-stream,' 'dual-stream,' or 'source separation recycling,' keeping materials separate by type helps to build a stronger and more effective recycling process overall. Clean materials retain their value, are easier to reuse, and make higher quality recycled materials. Clean-stream materials help feed the recycling loop by ensuring a steady supply of recycled material for manufacturers.

CUSTOMIZE YOUR CLEAN-STREAMS

The beauty of clean-stream programs is how infinitely customizable they are. The 1,700 residents of Kamikatsu, Japan sort used materials with an almost obsessive focus: with 34 bins for separate categories as wide-ranging as hole-less, matching sock pairs to empty and rinsed tofu containers, they provide a very extreme example. After nearly 13 years into its aggressive program, the town is at 80% diversion - well on the way to its Zero Waste goal. While we can all learn valuable lessons about sorting education, training, and diligence, successful clean-stream programs need not be so complex.

In fact, depending on what materials your business regularly discards, a sophisticated and successful source-separation program will likely only require very minimal site changes. For instance, if you're a dry cleaning company, we imagine you process a lot of cardboard and metal hangers. Recycling cardboard and paperboard in one bin and collecting the hangers separately from the trash in another will already save you landfill disposal costs, boost your recycling rates, and help feed our raw material economy. Universities and Property Management Groups see significant cost savings and massive leaps in sustainability goals by implementing simple clean-stream programs that emphasize collection of the used materials with highest volumes.

The simple act of keeping materials clean can make a huge difference! In the comments section below, let us know how your office likes to recycle - and whether you have any questions about how best to recycle more. Thanks, as always, for reading with us!